Foiling for Print

If you’ve ever admired metallic, shiny logos and text on packaging sleeves, flyers, or product packaging, you may be looking at the results of foil stamping, which is a subtle but beautiful way to enhance printed designs. At Packaging Sleeves, you can add foiling to your print run using digital foiling or hot foil stamping. Here’s a quick guide to both methods and which one would be the best option for your printing needs.

Digital Foiling

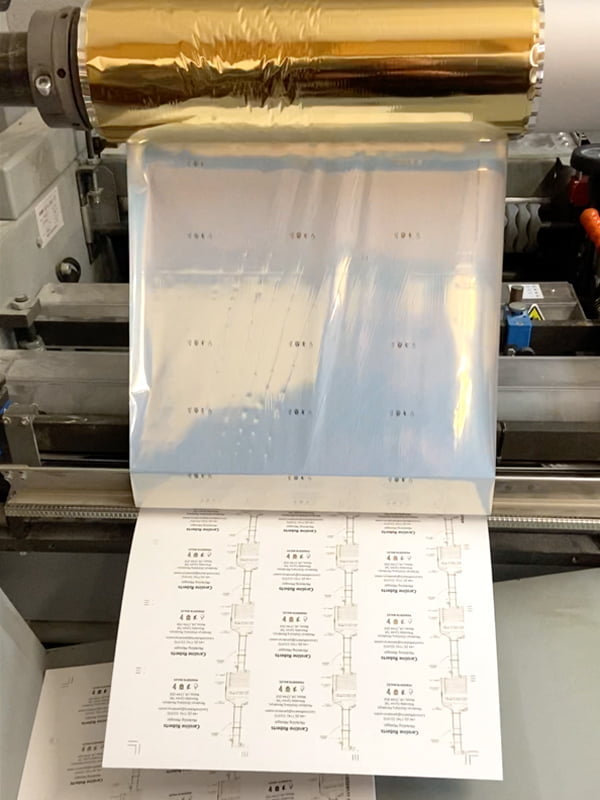

Digital foiling is a cost-effective and fast way to add foil to your packaging sleeves or other printed materials. All that is required is a digital artwork file that tells the digital foil machine where to print the foil onto the paper. Digital foiling is suitable for shorter print runs and offers quicker production times than hot foil stamping. However, digital foiling generally requires a laminated surface to achieve a good result, limiting the available finish options. Additionally, digital foiling cannot achieve the same level of presentation quality as hot foil stamping since the foil sits on the surface of the print rather than being debossed into the paper.

Digital foiling at Better Printing

Hot foil stamping

If you are looking for high-quality and luxurious foiling, hot foil stamping is the best option. This technique uses a press equipped with a custom-made die, the paper to be stamped, and a foil sheet that goes in between. The die plate is heated and then pressed onto the foil and printed item, resulting in the transfer of the foil onto the paper only where the die makes contact.

Additional fee. Assembling a custom-made die requires an additional cost that varies depending on the area you want to foil on your printed items. This extra cost is more significant if you are looking for a small quantity of foil-stamped items.

Custom brass die block for foiling

Coloured hot stamping foils

The pros of hot foil stamping:

Hot foiling offers a more refined finish, especially for small or delicate text, and the stamping process gives the foiled elements a subtle shimmer under light due to the slight debossing. It’s also more cost-effective for larger print runs compared to digital foiling, which is more economical for smaller quantities.

The cons of hot foil stamping:

Hot foil stamping requires more time to set up because a die block needs to be created, so digital foiling is a better option for urgent orders. Packaging Sleeves offers both hot foil stamping and digital foiling in-house from their print factory in Southampton.

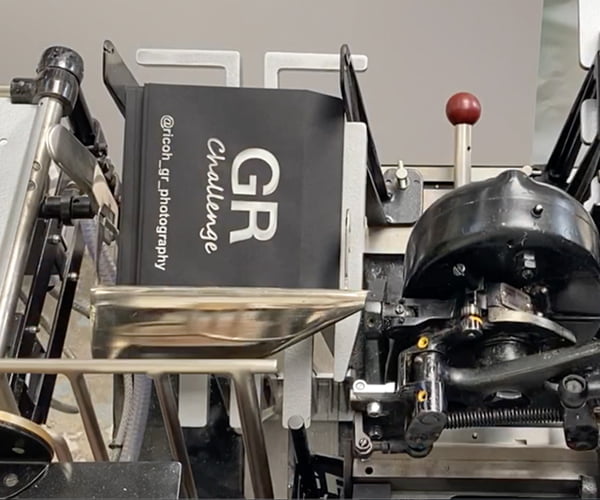

Hot foil stamping machine

If you have any additional questions about any type of foiling then call us on 023 8087 8037 or email us.