Die Cutting Explained

Die-cutting is a process used to cut materials into specific shapes using a die or cutting tool. This process is often used in printing to create custom-shaped products, such as labels, packaging, and business cards.

What is Die Cutting

In the world of printing, die cutting is a cost-effective and efficient method for cutting many packaging sleeves into identical shapes.

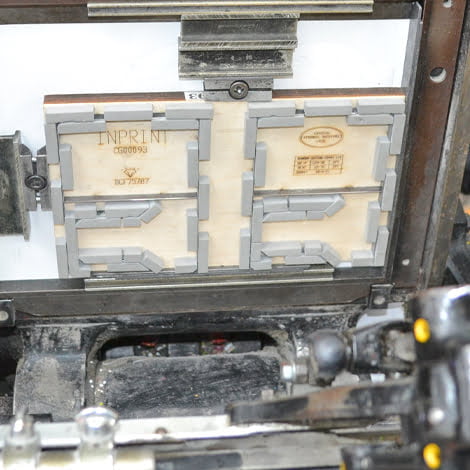

Your packaging sleeve design is first printed on a square or rectangular sheet of material, such as paper or cardstock. The printed material is then placed in a die-cutting machine loaded with a custom-made die or punch block. The die is typically made of wood with a metal blade bent and folded into the desired shape of the packaging sleeve.

When the die-cutting machine applies pressure to the printed material and the die, it quickly cuts out the shape of the blade into the packaging sleeve material, creating identical custom-shaped packaging sleeves.

Die cutting is for more than just eye catching custom shaped flyers however, it also helps create the more functional aspects of printed products such as pockets and flaps on folders and boxes plus the curves, circles and intricate interlocking elements on our speciality print.

Die cut block

Block mounted on platten

Custom cut boxes

Why is die-cutting beneficial?

Die-cutting is an excellent technique to create custom-shaped packaging sleeves efficiently, without the need for a time-consuming digital cutter to navigate around curves and corners. Once you have created your die or punch block, you can use it repeatedly to produce hundreds of identical packaging sleeves in the desired shape.

Which materials can be die-cut?

The punch-out style of cutting in die-cutting makes it ideal for low strength materials such as paper and cardstock. The recommended minimum paper weight for die-cutting packaging sleeves is 170gsm (approximately 140micron), while the maximum is 500gsm (approximately 600micron). Microns are the measurement of thickness, representing thousandths of a millimeter.

What about foamboard, correx and dibond?

For heavier and larger format materials used for packaging sleeves, digital die-cutting is required. Unlike die-cutting that uses physical dies, digital cutting relies on a blade following a computer-programmed path to create the custom shape.

A digital cutting machine for packaging sleeves includes a flat table area and a set of cutting, milling, and scoring attachments mounted on an arm. The arm allows the cutter to move left, right, forward, and backward.

To digitally die-cut a printed sheet for packaging sleeves, the sheet is placed on the table, and the cutter travels along the programmed path to cut out the shape required. This process is an alternative to traditional die-cutting for heavier and larger format materials.

Digital die cut paper and card

Digital die cutting technology offers “die free” cutting on a variety of paper and card weights, reducing production times and costs by eliminating the need for expensive die blocks. Though it may not match the output volume of traditional die cutting, digital die cutting is ideal for small print runs or prototypes of larger die cutting forms. This technology can be particularly advantageous for creating packaging sleeves.

Digitally cut cake box

If you have any more questions about die cutting, traditional or digital call us on 023 8087 8037 or email us.