Bleed Explained

Packaging Sleeves utilizes a print guillotine, equipped with tungsten and high-speed steel blades, to achieve precise and clean cuts on hundreds of paper sheets. While the guillotine ensures accuracy, there is a possibility of micro movement leading to white areas on the corners of the print. To avoid this, it is recommended to include overprint or “bleed” around the edges of the artwork. This technique is particularly important for creating packaging sleeves. Keywords: packaging sleeves, print guillotine, tungsten steel, high-speed steel, micro movement, overprint, bleed, artwork, white areas, precise cuts.

How much bleed do I need?

For optimum results in creating packaging sleeves, it is recommended to extend any images, background colors, or patterns to the end of a 3mm area added all around the document.

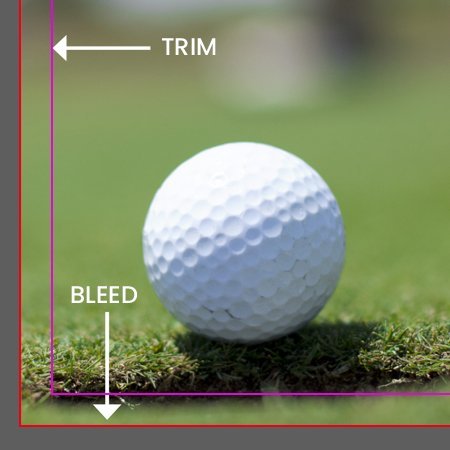

Document set up with no bleed

Document set up with 3mm bleed

Exported PDF with bleed and crops

How do i add bleed to my document?

Indesign

Under File > Document set up in the dialog box that says bleed and slug click into the bleed part and add 3mm on each side.

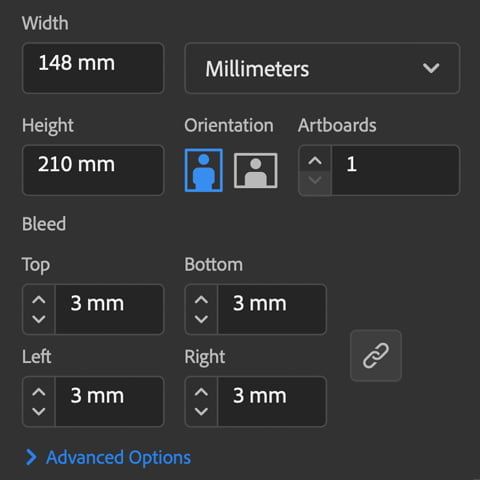

Illustrator

Similar to indesign except File > New will bring up the document dialog box, add 3mm to all sides.

Photoshop

Photoshop does not have a bleed setting so we recommend setting up your document 3mm bigger all around, so if document is to be printed A4 (210x297mm) set up as 216 x 303mm.

Illustrator bleed dialog box

Safe Area

To ensure a visually appealing design for your packaging sleeves, it is important to work within a safe area or “margin,” distinct from the bleed. This margin is situated within the artwork and typically reserved for important information, text, or headings overlaid on the background area. While the type layout may appear fine when it is a few millimeters from the edge on the screen, it can appear cramped and uneven once printed on the chosen material. It is recommended to maintain a margin of at least 5mm for smaller printed items and up to 25mm for larger items like banners. Keywords: packaging sleeves, safe area, margin, bleed, visually appealing design, important information, text, headings, background area, type layout, smaller printed items, larger items, banners.

Safe Area

To keep your artwork looking clean and aesthetically pleasing we recommend working with a safe area or ‘margin’, not to be confused with bleed this area sits within the artwork and is generally used for text and headings or important information on top of your background area, your type layout on screen can look fine if its a couple of millimetres in from the edge but once it is printed onto its chosen material it will appear cramped and uneven.

We recommend a margin of at least 5mm for smaller printed items and for larger items such as banners go up to around 25mm.

If you are unsure about bleed and your artwork or have any questions then call us on 023 8087 8037 or email us.